Foaming agent unit:

Standard Configuration for foaming agent injection adopts 3 separate units of injection systems, for CO2, ethonal, and third agent (Freon, DME, Butane, or others).

CO2 properties and foaming process requirements:

1. The concept of supercritical foaming: supercritical CO2 foaming technology. Carbon dioxide in temperature above the critical temperature (Tc) 31 ℃, 3 mpa pressure is higher than critical pressure (Pc), under the condition of nature change, its close to liquid density, viscosity to gas, liquid diffusion coefficient for 100 times, and thus has a strong ability to dissolve, this state is CO2 supercritical state.

2. Supercritical foaming requirements: CO2 supercritical state is determined by the temperature and pressure, because of the CO2 in the supercritical state has high diffusion coefficient, so the supercritical state is unstable, for application of supercritical foaming XPS production process is the need to have a stable working pressure, and the lower mold temperature. The CO2 injection also needs a stable flow, the process characteristics of XPS production equipment has significant improvement requirements are needed to meet.

Han plastic company CO2 XPS extruded insulation board production equipment technology security system:

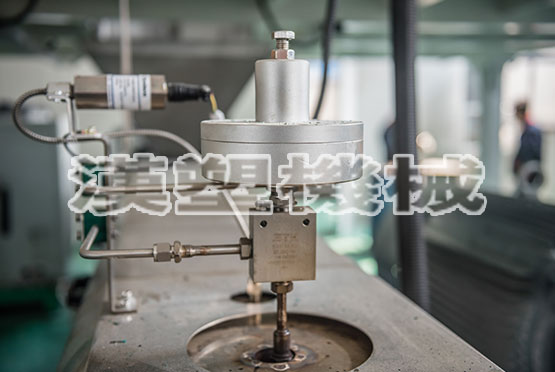

1, choose German production lind injection system

Features: pneumatic pump injection control, the whole chain pressure control and flow closed loop control. Injection stable accurate belongs to the world's top CO2 injection control technology.

2, choose German production riva pump injection

Features: three head diaphragm pump injection control, and flow meter combination form a closed-loop control system. Injection is stable.

CHINESE

CHINESE ENGLISH

ENGLISH